|

|

|

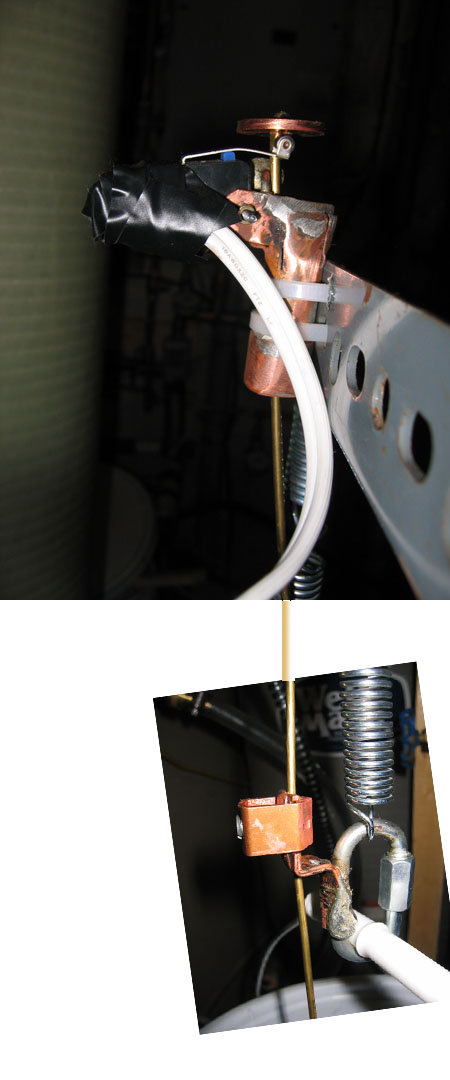

soldered to a carabiner

Saturday, April 8 2006

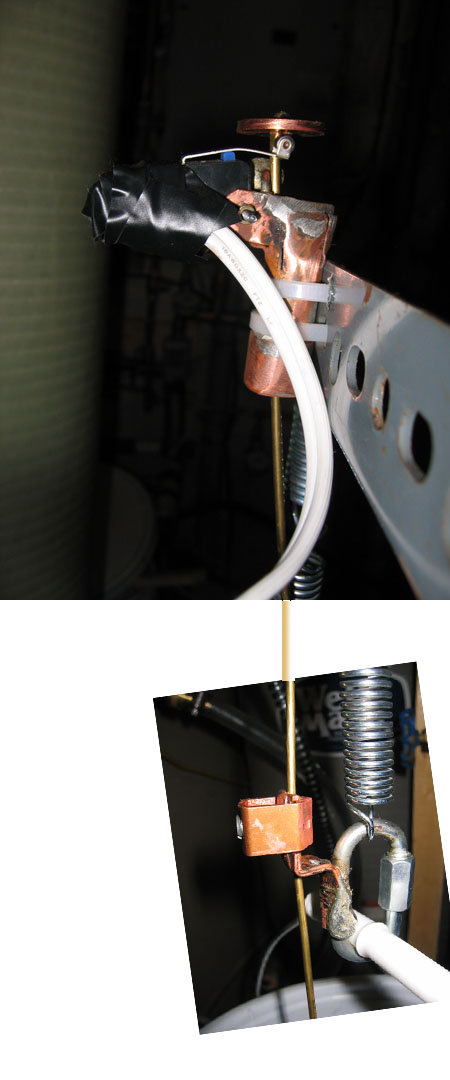

For the past few days I've been building a device that allows my antifreeze pump system to detect when the level of the antifreeze in the unpressurized reservoir (a five gallon bucket) falls below a certain amount. Most of the detector's hardware is copper or brass, materials I have in abundance and that I can easily connect together in arbitrary ways. Today I managed to get all of this detector's parts working together correctly.

The mechanism I'm using measures the weight of the bucket by simply hanging it by its handle on the end of a spring. The weight of the antifreeze in the bucket is directly proportional to how low the bucket hangs. If it hangs any higher than a certain level, there's an insufficient amount of antifreeze available and further pumping risks sucking air into the pump and destroying it. I've made it so that in this situation a leaf switch is turned off, vetoing any call by the under-pressure switch to pump more fluid into the pressurized part of the supply system.

The mechanism features a brass brazing rod topped with a copper disk. The upper part of the rod is held in position beside the leaf switch by a customized chassis made of soldered copper. Meanwhile the lower end of the rod is held by a wire ground clamped soldered to a steel carabiner that loops around the bucket handle. When the bucket hangs low enough, the disk pushes down on the leaf switch to allow electricity to flow to the pump. When the bucket contains less than a gallon of fluid, the spring pulls it up, along with the brazing rod and that disk of copper, opening the leaf switch and forbidding the pump from running. One interesting thing about this mechanism is that the copper disk which depresses the leaf switch is actually a plug of copper made by a small hole saw, a byproduct of those holes I had to cut through a four-inch copper cap during the successful homebrewing of that all-copper fluid-to-fluid heat exchanger back in January.

An overview of the mechanism just described. That copper clamp soldered to the carabiner allows me to adjust the level at which the leaf switch opens and closes.

For linking purposes this article's URL is:

http://asecular.com/blog.php?060408 feedback

previous | next |